Hot plasma core, cold edge – a masterpiece of control technique

ASDEX Upgrade fusion device breaks record for power exhaust / results of power plant relevance

Like the sun, a fusion power plant is to derive energy from fusion of atomic nuclei. The fuel – an ionised low-density hydrogen gas, a “plasma” – has to be confined in a magnetic field cage for this purpose, scarcely touching the vessel wall. In this way, the ultra-low-density gas can be heated to ignition temperatures exceeding 100 million degrees.

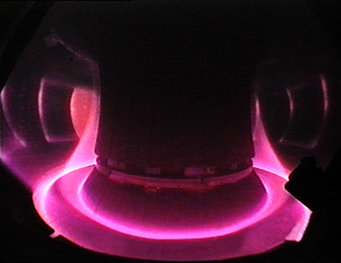

One of the major challenges here is to achieve moderate interaction between the plasma vessel and the hot plasma enclosed. Particular attention has to be paid to the places where the plasma is in contract with the wall: A special magnetic field, the divertor field, guides the outer edge of the ring-shaped plasma to particularly robust, cooled plates at the bottom of the vessel. Perturbing impurities are thus extracted from the plasma. Also the vessel wall is safeguarded and, in addition, the hot interior of the plasma is effectively separated from the colder shell: The boundary layer formed by the divertor field wraps the core plasma like a warming blanket, this being the prerequisite for good thermal insulation.

The thermal load on the divertor plates envisaged for a power plant is about 5 megawatts per square metre. In order not to exceed this value, the aim is to make the plasma edge as cold as possible and yet keep the core at 150 million degrees. The necessary thermal insulation is ensured primarily by the shell-structured magnetic field, which sharply decelerates the transport of particles from the hot plasma core to the outside. This was enhanced in ASDEX Upgrade. The plasma edge was actively cooled by injection small amounts of argon into the main space and of nitrogen directly in front of the divertor plates.

The injected impurity particles are excited to luminescence on contact with the hot plasma. The energy is thus gently removed from the plasma as ultraviolet or x-ray light. Unlike in the hot core, where this cooling effect of impurities has to be avoided, it is very useful at the edge of the plasma: Before the fast plasma particles impinge on the divertor plates, they have already lost their energy to the nitrogen and argon atoms.

The record-breaking method

The heating power thus deposited in the comparatively small plasma is a world record: The hitherto unattained heating power of 14 megawatts per metre with respect to the radius of the device was achieved without overloading the divertor plates.

In order to set the heat flux to the divertor plates exactly in all phases of the discharge the nitrogen and argon inputs were separately controlled by a sophisticated real-time feedback control system, the world’s first ever. Measuring instruments record the energy emitted in the main space and in the divertor at the plasma edge, from which the power flow to the divertor plates in calculated. If it is too high, more nitrogen or argon is immediately injected. If insufficient power is obtained, the gas valves are throttled within milliseconds. This masterpiece of control technique always keeps the divertor load in the target range for a future power plant, despite the high heating power of 23 megawatts for the three-milligramme plasma of ASDEX Upgrade. At the same time the core plasma exhibits the high purity, high temperature and good insulation desired. “We are confident”, states Project Head Prof. Dr. Arne Kallenbach, “that by this method it will also be possible to master the much higher power fluxes in a future power plant”.

Isabella Milch